zachary.wilson

Member

Howdy Everyone,

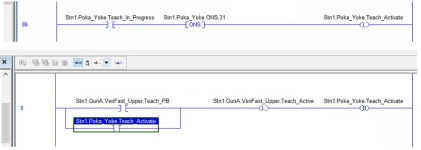

So I have been retrofitting a cell to run different fixtures and updating it with new drives and a few other things. It runs Studio Designer. It is actually to take a couple of the removeable fixtures from one cell so we don't have to change them over. Some of the logic I just copied over and wasnt too worried about. But then when it went to run it didn't work. After digging for a while I found I wasn't getting OTL energized to finish out the cycle, I followed the bit that makes the line tru back to other routines, where I found an OTE getting turned on by one bit with a ONS after it. I tried a couple different ways to make sure it was happy, before I ultimately got rid of the ONS and put a timer and a TT bit that ran for 2 seconds. I would normally assume it was because it didn't have enough time to register in a completely different program. But the weird thing is, the routine with the ONS in it, was a copy from another PLC, that runs fine.

Does anyone have any idea other than i am just missing it because of scan times?

I always assumed an ONS stayed on for 1 scan of the entire program, is it just for that routine, and it just happens to work in the other program? thank you. I attached the two rungs of logic, they are in different containers. it was identical between the two machines, but only worked on one of them.

So I have been retrofitting a cell to run different fixtures and updating it with new drives and a few other things. It runs Studio Designer. It is actually to take a couple of the removeable fixtures from one cell so we don't have to change them over. Some of the logic I just copied over and wasnt too worried about. But then when it went to run it didn't work. After digging for a while I found I wasn't getting OTL energized to finish out the cycle, I followed the bit that makes the line tru back to other routines, where I found an OTE getting turned on by one bit with a ONS after it. I tried a couple different ways to make sure it was happy, before I ultimately got rid of the ONS and put a timer and a TT bit that ran for 2 seconds. I would normally assume it was because it didn't have enough time to register in a completely different program. But the weird thing is, the routine with the ONS in it, was a copy from another PLC, that runs fine.

Does anyone have any idea other than i am just missing it because of scan times?

I always assumed an ONS stayed on for 1 scan of the entire program, is it just for that routine, and it just happens to work in the other program? thank you. I attached the two rungs of logic, they are in different containers. it was identical between the two machines, but only worked on one of them.