Cyanogen281

Member

I am using a Siemens s7-300 PLC and need to add a second wet well level.

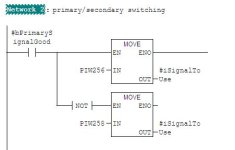

Basically the system will utilize the primary wet well level transmitter, but if for some reason the primary transmitter is malfunctioning the system will automatically switch to the auxiliary transmitter.

I am using a Maple system HMI for graphic interface.

How would I write the fail-over logic?

Any advice or examples would be greatly appreciated.

Basically the system will utilize the primary wet well level transmitter, but if for some reason the primary transmitter is malfunctioning the system will automatically switch to the auxiliary transmitter.

I am using a Maple system HMI for graphic interface.

How would I write the fail-over logic?

Any advice or examples would be greatly appreciated.