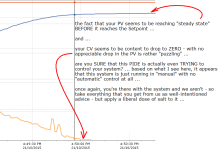

This is a compactlogix with PIDE block, you can't write to the internal variables at all.

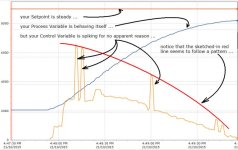

I-PD would work the same wouldn't it? It appears the CV spiking is due to the change in PV, eg if it uses error or simply PV it would still see a large rate of change in the PV causing the error term to increase.

My solution so far is to use a Kp of 0.5 and Ki of 30 repeats/minute which works but I would like to be able to use the Kp as well.

I-PD would work the same wouldn't it? It appears the CV spiking is due to the change in PV, eg if it uses error or simply PV it would still see a large rate of change in the PV causing the error term to increase.

My solution so far is to use a Kp of 0.5 and Ki of 30 repeats/minute which works but I would like to be able to use the Kp as well.