hardaysknight

Lifetime Supporting Member

We run multiple products on our machines, which means we have multiple robot programs that we swap to, due to the points for the robots having to be different.

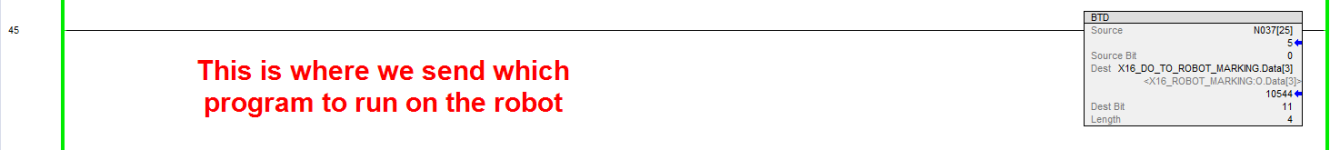

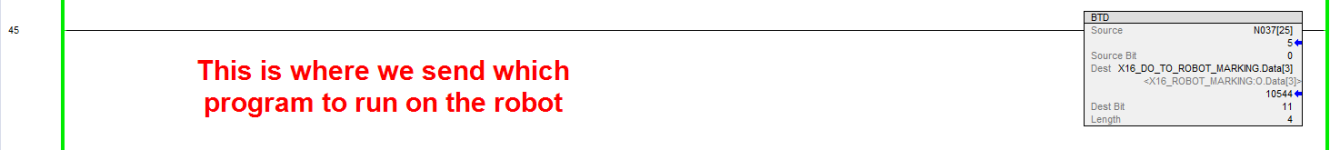

Our PLC sends ~3 integers to the robot for I/O. One of these integers is a product number. If we send a "5" in that integer, the robot changes programs (the robot loads a different *.pgf file stored on the robot controller). However, I see this integer changing in Studio5000, but there is nothing that I could see in the ABB EIO file to allow the robot to do this. It currently works, but I have no idea how.

I'm attaching a screenshot of where we send the robot program in the PLC, and the ABB EIO file if anyone wants to take a look at it.

Our PLC sends ~3 integers to the robot for I/O. One of these integers is a product number. If we send a "5" in that integer, the robot changes programs (the robot loads a different *.pgf file stored on the robot controller). However, I see this integer changing in Studio5000, but there is nothing that I could see in the ABB EIO file to allow the robot to do this. It currently works, but I have no idea how.

I'm attaching a screenshot of where we send the robot program in the PLC, and the ABB EIO file if anyone wants to take a look at it.