Hi:

I am trying to understand the configuration of the analog inputs from a PLC 5-20. It is an 1771-IFE/C module, and it's using all the 16 channels. I have the Analog Input User Manual that is in http://samplecode.rockwellautomation.com/idc/groups/literature/documents/um/1771-um663_-en-p.pdf

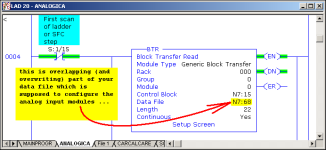

The program has a BTW instruction to configure the Module which is located at Rack0 Module 0 Group4. So the BTW is like this:

Rack -----------000

Group ----------4

Module ---------0

Control Block --N7:10

Data File ------N7:36

Length ---------16

Continuous -----No

The BTR goes like this:

Rack -----------000

Group ----------4

Module ---------0

Control Block --N7:25

Data File ------N7:112

Length ---------22

Continuous -----Yes

To begin with I don't understand the chart in page 39 (4-7) of the manual, where it says that if I want to use 16 channels I have to do a BTW instruction of length 37 and a BTR of 20.

In my PLC I AM using the 16 channels (i know because it is working) and those lenghts do not match with the ones in the chart. There is something I am not getting...

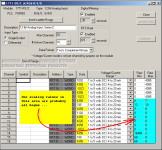

Secondly: The Control Block of the BTW is N7:36, This Block goes like this in Hex/BCD:

Offset..0....1....2....3....4....5....6....7....8....9

N7:30 ..0....0....0....0....0....0....0....0....2C30.0

N7:40 ..0....0....4095.0....4095.0....4095.0....4095.0

N7:50 ..4095.0....7....C..............................

Because of the operations it uses then on the read data I guess my application doesn't uses scaling, so I don't understand why it defines the min/max values for some channels, and not for all of them or none at all.

Obviously I'm not understanding this scaling feature, Can some of you help me?

Thank you very much for your time.

I am trying to understand the configuration of the analog inputs from a PLC 5-20. It is an 1771-IFE/C module, and it's using all the 16 channels. I have the Analog Input User Manual that is in http://samplecode.rockwellautomation.com/idc/groups/literature/documents/um/1771-um663_-en-p.pdf

The program has a BTW instruction to configure the Module which is located at Rack0 Module 0 Group4. So the BTW is like this:

Rack -----------000

Group ----------4

Module ---------0

Control Block --N7:10

Data File ------N7:36

Length ---------16

Continuous -----No

The BTR goes like this:

Rack -----------000

Group ----------4

Module ---------0

Control Block --N7:25

Data File ------N7:112

Length ---------22

Continuous -----Yes

To begin with I don't understand the chart in page 39 (4-7) of the manual, where it says that if I want to use 16 channels I have to do a BTW instruction of length 37 and a BTR of 20.

In my PLC I AM using the 16 channels (i know because it is working) and those lenghts do not match with the ones in the chart. There is something I am not getting...

Secondly: The Control Block of the BTW is N7:36, This Block goes like this in Hex/BCD:

Offset..0....1....2....3....4....5....6....7....8....9

N7:30 ..0....0....0....0....0....0....0....0....2C30.0

N7:40 ..0....0....4095.0....4095.0....4095.0....4095.0

N7:50 ..4095.0....7....C..............................

Because of the operations it uses then on the read data I guess my application doesn't uses scaling, so I don't understand why it defines the min/max values for some channels, and not for all of them or none at all.

Obviously I'm not understanding this scaling feature, Can some of you help me?

Thank you very much for your time.