That screenshot is a little blurry; try trimming it and saving as *.PNG instead of *.JPG.

I think I understand that your CompactLogix is the connection originator, and that the Unitronics is acting as the connection target. The connection target is sometimes also called the "Adapter".

It looks like the second field is labeled "O2T Assembly" and "EtherNet/IP Inputs" with a value of 100.

"O2T" probably means "Originator to Target", so I think that Assembly 100 is the Input assembly from the Unitronics perspective, and the Output assembly from the CompactLogix perspective.

Similarly, the fifth field is labeled "T2O", meaning data that's flowing from the Target (Unitronics) to the Originator (CompactLogix). Assembly 101 is Output data from the Unitronics perspective, and Input data from the CompactLogix perspective.

The sizes are in Bytes, and one is an odd number, so the Generic Ethernet Module object needs to be defined in SINT datatype tags.

As with so many other things in electronics, if the Input and Output sizes and numbers don't seem to work, try swapping them. Don't worry, nothing will short out.

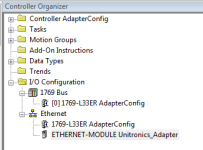

Here's a screenshot of how I think the CompactLogix I/O object should be configured: