KarajoSoft

Member

Dear colleagues,

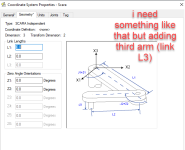

hope you can help on that matter. We have a project where we need to control 3 servomotors to move a auger feeder system (feeding is constant) to fill one area.

the tricky point here, is how to consider the program to be able to move these 3 servomotors synchronously and make the auger move throughout the area until the hopper is completely filled with product. How can do it?

I think there is some kind of library to control robot of 6 axis using kinetix 5700, but maybe there is better ideas here from some experienced colleague. To detect all the area is filled will install some kind of sensor or artificial vision.

Please find image attached for better understanding.

any suggestions are most welcome.

many many thanks!

hope you can help on that matter. We have a project where we need to control 3 servomotors to move a auger feeder system (feeding is constant) to fill one area.

the tricky point here, is how to consider the program to be able to move these 3 servomotors synchronously and make the auger move throughout the area until the hopper is completely filled with product. How can do it?

I think there is some kind of library to control robot of 6 axis using kinetix 5700, but maybe there is better ideas here from some experienced colleague. To detect all the area is filled will install some kind of sensor or artificial vision.

Please find image attached for better understanding.

any suggestions are most welcome.

many many thanks!