ivanjoseph21

Member

Hi Everyone,

Would like to ask about something we encountered on our work and would like some advise.

We are upgrading a SLC controller to a ControlLogix. However, we are maintaining the current RIO setup as shown in the picture. Using a DHRIO to communicate with the Remote IOs (1794-ASB).

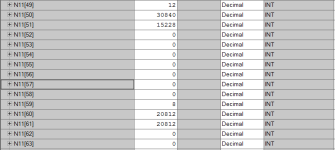

During our initial, almost all IOs are OK including the Analog Input. However, we are not measuring any analog output during our test. I believe the msg for the Analog is similar (inverse). I've attached a sample.

Is there any probable cause for this?

Would like to ask about something we encountered on our work and would like some advise.

We are upgrading a SLC controller to a ControlLogix. However, we are maintaining the current RIO setup as shown in the picture. Using a DHRIO to communicate with the Remote IOs (1794-ASB).

During our initial, almost all IOs are OK including the Analog Input. However, we are not measuring any analog output during our test. I believe the msg for the Analog is similar (inverse). I've attached a sample.

Is there any probable cause for this?