Bobobodopalus

Member

Hi all

I was being really clever and suggested i add a list of preset settings to a line which every1 seemed thrilled with. however the amount of tedium has just dawned on me.

im hoping theres a better way to go about this.

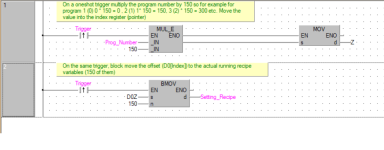

the main idea is that we have a line controlled from a cj2m which has around 150 changeable settings including things like conveyor speeds, pump filling times.. waiting times etc..

i have done this in smaller scale before where we had changeable pumps, when pump 1 was connected i used the MOV function to load pump 1's data into the correct words.

and in NB designer i had layered multiple number input boxes each displaying only when its own pump was connected.

any ideas would be great

I was being really clever and suggested i add a list of preset settings to a line which every1 seemed thrilled with. however the amount of tedium has just dawned on me.

im hoping theres a better way to go about this.

the main idea is that we have a line controlled from a cj2m which has around 150 changeable settings including things like conveyor speeds, pump filling times.. waiting times etc..

i have done this in smaller scale before where we had changeable pumps, when pump 1 was connected i used the MOV function to load pump 1's data into the correct words.

and in NB designer i had layered multiple number input boxes each displaying only when its own pump was connected.

any ideas would be great