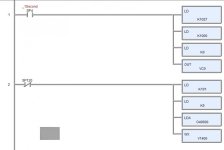

Ok so I managed to get rid of the I/O address error by correcting the port address of the D0-DCM module from 1 to 2 in the second rung, first 'LD' box. It was changed from K101 to K201. The screenshot of the D0-DCM manual below will show what that box means specifically. It still does not move the x-axis though.

Also, I believe that I have to change the special relay function from SP120 to SP122 because SP122 relates to slot 2. See manual screenshot below to confirm. Still nothing...

The 5 in the second box on the second rung is the number of bits transmitted. It should be set to 8 I believe, not 5. Regardless, the 5 in the formula should be in mm, as in the gantry travels 5mm per 1 full rotation of the motor.

The third box is where I am slightly lost. Its description is outlined in appropriately titled image below. What address am I supposed to be loading the memory from?/ Where in the coding am I saving the position formula to? Is it the first rung that should describe the distance moved based on the formula given? If so, then should I write the fourth box on the first rung, 'OUT', to the same V-memory address as the second rung, third box, 'LDA', that I am calling?

Box 4 is pretty straight forward but what starting address and data type are correct for the slave?/How would I go about finding this out?

Attached below is a screenshot of the updated program that I tweaked so you can see exactly what I'm talking about.