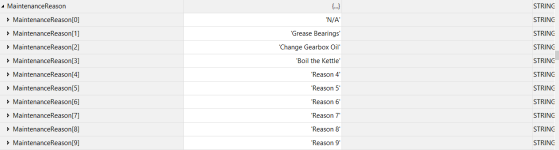

Hello, I'm working on a project using an Allen-Bradley 1769-L30ER v31 and a Panelveiw Plus7 v11. I have an AOI that keeps track of the time a piece of equipment has been running and triggers a message when a preset time has been reached (for maintenance purposes). As the equipment is subject to change I would like to enable the plant manager to change the name of the preset times where they are entered in the HMI. For example it could be changed from Grease Bearings to Change Gearbox Oil. My question is, is there a way do do this or effectively or is more trouble than its worth? I could just call them some thing like TMR Scheduled Maintenance 1 and 2 but that would likely result in them having to keep track of a maintenance legend or schedule (for a bit more context this a homebuilt farmer-operated feed mill). Any guidance would be appreciated.

Enabling the supervisor to rename data in the HMI

- Thread starter Code_E

- Start date

Similar Topics

Hi all, I'm having trouble connecting and running an SEW motor from an Allen Bradley PLC and MOVIFIT FC. I'm using Studio5000 V23 and MOVITOOLS...

Hello I am trying to enable Visual Basic for FactoryTalk SE v.10.0. I have a coworker who has it enabled on his v.9.0 but he cannot remember how...

Hey,

I'm used to CompactLogix 5000 controllers and was needing to know the process of forcing on bits and enabling forces on a SLC 500 Allen...

Let's say you have a converted app from a 1400e. The alarm banner pops up, but none of the buttons are touchable. I don't see any settings that...

Greetings All!

Preface: I am a complete "fresh out of the womb"-type novice when it comes to PLC programming. I helped get a Logix 500 PLC up and...