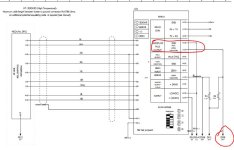

This the problem guys

I am installing flow meters at different sections of the plant to measure %loss in production.

Since the flow meters are there I also want to use them to produce figures of production over each shift.

I would think that I should integrate the flow rate in order to obtain this figure.

How exactly do I write the ladder logic for this application.

Hardware: Allen Bradley PLC5 Enhanced

Software: RSLogix5

And if there is anyone with this information I also wanted to know what are some of the common errors that exist with this system

I am installing flow meters at different sections of the plant to measure %loss in production.

Since the flow meters are there I also want to use them to produce figures of production over each shift.

I would think that I should integrate the flow rate in order to obtain this figure.

How exactly do I write the ladder logic for this application.

Hardware: Allen Bradley PLC5 Enhanced

Software: RSLogix5

And if there is anyone with this information I also wanted to know what are some of the common errors that exist with this system

Last edited: