I asked this question briefly in my previous post long post, I'm asking again here as the main point so it doesn't get buried. I am pretty new at this so I am expecting to have overlooked something simple.

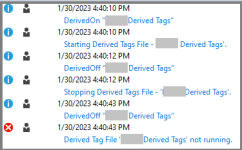

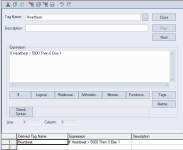

I have a factory talk SE distributed network server and was learning how to use derived tags to have the server communicate to a PLC. I right clicked the component and clicked start. The expression worked fine, it's running right now turning a bit off and on PLC side.

Next, I right clicked the component again and clicked stop. It never stopped.

I tried running DerivedOff on the component. I tried deleting the component and restarting the SE server. Restarting the SE server stopped the expression until it was rebooted.

Anyone have an idea for me?

I have a factory talk SE distributed network server and was learning how to use derived tags to have the server communicate to a PLC. I right clicked the component and clicked start. The expression worked fine, it's running right now turning a bit off and on PLC side.

Next, I right clicked the component again and clicked stop. It never stopped.

I tried running DerivedOff on the component. I tried deleting the component and restarting the SE server. Restarting the SE server stopped the expression until it was rebooted.

Anyone have an idea for me?