sp_

Member

Hi,

I am still a beginner with PLCs and I have never worked with GE PLCs before so looking for some help.

I am using GE Proficy Machine Edition v9.5

I was given the PLC code already written. I have to download the program to the PLC and HMI. The system is using a Versamax Micro Plus Controller - IC200UDR064-EK and a QuickPanel+ HMI -IC755CSS06RDA-CR. I was able to download the program into the HMI via the serial port. I set the IP on the HMI and was able to download the HMI as well. The PLC has an ethernet module - IC200UEM001-DF. I was able to set the IP using the Telent method I found online. I have a Weidmuller remote IO module - UR20-FBC-MOD-TCP-V2 - connected via ethernet. I have configured the module with an IP address as well. All 3 modules are connected to an unmanaged switch. I can ping all of the devices with the IPs I have set.

The question I have is how do I configure the Weidmuller remote IO module in the GE program?

When I look at the hardware configs, there is no ethernet module and the option to add module is greyed out.

Do I add another Target to reach the remote IO? But when I go to add target all I see are GE modules. So how do I configure the remote IO in the program?

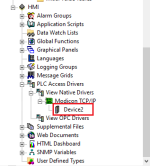

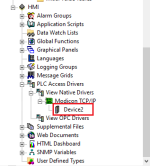

Could it be under PLC Access Drivers? Even if I set the IP for the "Device2" as the IP for the remote IO, it still doesn't seem to communicate with the PLC as I see a Bus Failure LED on the remote IO, which according to the manual is No connection to the Fieldbus - Check the Fieldbus cable and the PLC configuration. (Tested the cable - it is fine)

How do we add non-ge remote IO modules to a get project and configure it?

Where in the project tree will I find the remote IO data? Like where do I view the inputs and outputs related to the IO module?

I am still a beginner with PLCs and I have never worked with GE PLCs before so looking for some help.

I am using GE Proficy Machine Edition v9.5

I was given the PLC code already written. I have to download the program to the PLC and HMI. The system is using a Versamax Micro Plus Controller - IC200UDR064-EK and a QuickPanel+ HMI -IC755CSS06RDA-CR. I was able to download the program into the HMI via the serial port. I set the IP on the HMI and was able to download the HMI as well. The PLC has an ethernet module - IC200UEM001-DF. I was able to set the IP using the Telent method I found online. I have a Weidmuller remote IO module - UR20-FBC-MOD-TCP-V2 - connected via ethernet. I have configured the module with an IP address as well. All 3 modules are connected to an unmanaged switch. I can ping all of the devices with the IPs I have set.

The question I have is how do I configure the Weidmuller remote IO module in the GE program?

When I look at the hardware configs, there is no ethernet module and the option to add module is greyed out.

Do I add another Target to reach the remote IO? But when I go to add target all I see are GE modules. So how do I configure the remote IO in the program?

Could it be under PLC Access Drivers? Even if I set the IP for the "Device2" as the IP for the remote IO, it still doesn't seem to communicate with the PLC as I see a Bus Failure LED on the remote IO, which according to the manual is No connection to the Fieldbus - Check the Fieldbus cable and the PLC configuration. (Tested the cable - it is fine)

How do we add non-ge remote IO modules to a get project and configure it?

Where in the project tree will I find the remote IO data? Like where do I view the inputs and outputs related to the IO module?