Hi to the forum.

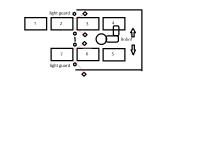

I have a logic problem which is confusing me. From my sketch I have seven conveyors that I control using a twido PLC via canbus.

number 4 & 5 conveyors goes up & down for the robot to pick & place boards. Input Light guard through safety relay to plc x 2 - output to halt robot.

All working fine(still commisioning) until they enclosed the machine and installed cat2 light guards. The idea is to halt the robot only (suppose if one jumps into the cell) .. now the confusion ... if a pallet is not passing through. on each conveyor is a switch at the end so one knows if there is a pallet. There is a hard wired Reset button.

I was wondering if someone could put me out of my misery... I know there is some logic that I can follow but what ?

I have a logic problem which is confusing me. From my sketch I have seven conveyors that I control using a twido PLC via canbus.

number 4 & 5 conveyors goes up & down for the robot to pick & place boards. Input Light guard through safety relay to plc x 2 - output to halt robot.

All working fine(still commisioning) until they enclosed the machine and installed cat2 light guards. The idea is to halt the robot only (suppose if one jumps into the cell) .. now the confusion ... if a pallet is not passing through. on each conveyor is a switch at the end so one knows if there is a pallet. There is a hard wired Reset button.

I was wondering if someone could put me out of my misery... I know there is some logic that I can follow but what ?