I have already a Zelio logic control with 8 digital inputs and 4 digital outputs and I will search in this topic to any ladder diagram to do it.

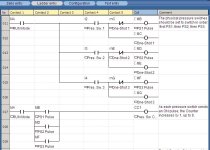

First make an outline of the program, listing all of your Outputs (Q1, Q2, Q3 for Pumps 1 to 3, Input I1 to I3 for your 3 Pressure Switches, Input I4 for a Reset Pushbutton, Internal relay bits M1 to M9 for your Pump Sequence Bits, and Counter C1 for the Pressure Switch Counter).

Looking at the instructions available for the ZelioSoft Ladder programs, there are no indirect addressing, or sequencer instructions. But there are Counters and Counter Comparators, so use a Counter (as mentioned by Garry way back in Post #2).

Pressure Switch Counter 1: Counts from 1 to 9 as the Pumps come ON then go OFF (Each of the 3 Pressure Switches cuts On then Off to trigger the Counter). The Pumps follow a sequence controlled by 9 "M" internal auxiliary relays (M1 to M9), then repeats.

1. When C1 = 1, M1 is activated (which runs Pump 1).

2. The next pressure switch activation moves the counter C1 to 2, and when C1 = 2, M2 is activated which starts Pump 2.

3. When C1 = 3, Pump 3 runs.

4. When C1 = 4, Pump 2 runs.

5. When C1 = 5, Pump 3 runs.

....(and so on up to step 9).

Each M relay runs a pump, until 9 runs are completed (M1 to M9). The 3 pumps will run in order controlled by a Pump Number sequence: Pumps 1, 2, 3; then 2, 3, 1; and then 3, 1, 2; then repeat the sequence as controlled by M1 to M9.

When Counter C1 = 9 and the pressure switch opens again, then the Counter and all control bits are reset to 0, and the cycle repeats.

Usually at this point, the beginner comes back and says "I forgot to mention that it needs to do this . . ." Now is the time to reveal all details. Going farther without the full infomration will lead to disaster (a non-working program).

Adding logic so that if a pump Overload is tripped or a breaker is off on one pump the run logic will be passed off to the next pump in the scheduled sequence is optional, but it will be very usefull if I do it.

Bonus Points? I suggest you use a timer set for about 5 seconds to determine if a pump has started. You will need 3 additional Inputs (I5, I6, and I7?) from the Pumps to determine if the pump started when told to start. If not, advance your C1 Counter by 1 using a M relay "Active on impulse relay edge" (or one-shot pulse) to start the next pump in the sequence.