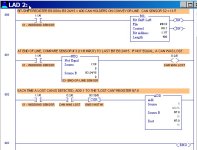

Hey guys I am new to these forums and I am relearning PLC's after a 10 year break from it. What I am trying to do is keep track of cans that get connected to a hang line. I only have Three sensors to do this with. There is 400 holders and not every holder gets a can depending on producton run time. right now i have a BSL set up that shows me which holder has a can and which does not. My question is how can I compare the bits and know is a can has fell. Two sensors are for seeing the can and holder going in to process and the last sensor is to see can come out. but with out spending alot of resources Any ideas or help I thank you in advance.

Help with SLC500 keeping track

- Thread starter bdingus76

- Start date

Similar Topics

Hello im hoping someone can point me in the right direction. I have a SLC-500 that the program has been erased. I'm being told it will require an...

Hello Guys,

I'm trying to get online with a SLC 500. I've never had issues going online with it before with the current program but now it keeps...

im using Slc5/04 one of its 8 channel analog output module 1746-NO8I got defective if i replace it with new one do i have to re-program or...

I am looking to see if somebody can assist me with a pdf copy of the attached SLC500 RSS file.

Thank you

Jeff

I am working on a conversion from a SquareD PLC to a SLC series PLC. I have run across one issue that I can not seem to overcome. The older system...