Hi guys

I need help from you

this is my last year in the university and I have a final project which is automatic controlled system

here you can read the Principle of Operation of my project :

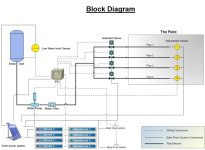

(you can see the diagram)

The Concept of this project starts from the field where there are some soil moisture sensors and it begin when the soil gets dry the soil moisture sensors will sense the moisture in the soil and the sensors will send signals to the PLC for taking an action and the Dry soil LED will be on to show that the field need watering. The PLC will activate the water pump and PLC will choose the water path by opening the solenoid valve for the needed field. On the other hand, The PLC will not operate the pump unless there is enough water in the tank. By using a level sensor otherwise the water pump will burn if the tank is empty. Moreover, when the soil gets wet the soil moisture sensors will sense that and that will be shown in the saturated indicator LED. Also, the Start and Stop Push buttons will be exist to active and stop the system.

the problem is how I can do the ladder diagrams for PLC???!!!

and I have 7 inputs and 12 outputs, what is the best plc module should be used ( I mean the fixed or the small plc ) and how the connections will be ?

Really I need help from you I have every thing expect the programming.

I need help from you

this is my last year in the university and I have a final project which is automatic controlled system

here you can read the Principle of Operation of my project :

(you can see the diagram)

The Concept of this project starts from the field where there are some soil moisture sensors and it begin when the soil gets dry the soil moisture sensors will sense the moisture in the soil and the sensors will send signals to the PLC for taking an action and the Dry soil LED will be on to show that the field need watering. The PLC will activate the water pump and PLC will choose the water path by opening the solenoid valve for the needed field. On the other hand, The PLC will not operate the pump unless there is enough water in the tank. By using a level sensor otherwise the water pump will burn if the tank is empty. Moreover, when the soil gets wet the soil moisture sensors will sense that and that will be shown in the saturated indicator LED. Also, the Start and Stop Push buttons will be exist to active and stop the system.

the problem is how I can do the ladder diagrams for PLC???!!!

and I have 7 inputs and 12 outputs, what is the best plc module should be used ( I mean the fixed or the small plc ) and how the connections will be ?

Really I need help from you I have every thing expect the programming.