Steve Bailey

Lifetime Supporting Member + Moderator

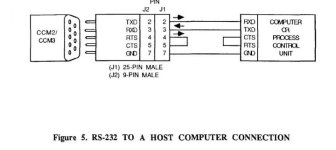

The publication number for the CCM2 module is GFK-0238A. It gives the details for setting the dip switches and jumpers to configure the serial ports on the module. The settings on the module for baud rate, parity, data bits and stop bits must match those for the kepware. If you are able to change the dip switch settings on the module without removing it from the rack, be aware that you must cycle power before the changes take effect.