dskplc

Member

Hello,

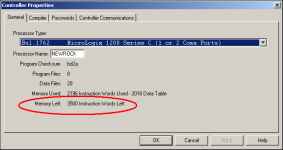

I changed controller type in RSLogix 500 from SLC 5/02 to MicroLogix 1200 and was given the ladder logic to update it for the new controller. The PID instruction for new ML 120 required creating a new data type. Now I think I have duplicate data in my software since I get an error message saying I have "exceeded my 2K memory for user data words". I have tried deleting unused memory but that creates more errors. I have experimented with changing to a ML 1400 but that creates read / write bit errors. Any ideas?! I have customer waiting for me to download this code and am at loss even after googling this. Thanks in advance.

I changed controller type in RSLogix 500 from SLC 5/02 to MicroLogix 1200 and was given the ladder logic to update it for the new controller. The PID instruction for new ML 120 required creating a new data type. Now I think I have duplicate data in my software since I get an error message saying I have "exceeded my 2K memory for user data words". I have tried deleting unused memory but that creates more errors. I have experimented with changing to a ML 1400 but that creates read / write bit errors. Any ideas?! I have customer waiting for me to download this code and am at loss even after googling this. Thanks in advance.