blueyedpeter

Lifetime Supporting Member

OP

The project this is why.

I actually Own a couple of plc,s and like i have been stating , code writing i am weakest at , my programs usually look like a hard wired attempt there's nothing fancy or stylish about how i write .

I know i have been vague about where i am going with this because i would have dribbled on far to long and you all would have written me off as a crazy with a lap top.

And granted i am starting to wonder if i have drooped a cog in trying to automate an exercise bike .

It would be far easer to go and buy the thing they are called amongst other things computrainer and sell for about $2400 US .

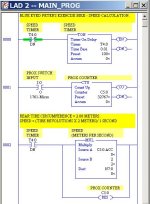

As for details it is rather simple i cant mount an encoder on the back wheel as it would get up to speeds of 6000 rpm , so a single prox input will do fine .

The other input is mounted near the rider, at the pedals and will monitor speed of the pedals , the maximum speed there is around 130 rpm

Things that will be measured include speed , distance , average power out put of the rider , there will be three load ranges hi med and low , there is a second load device that will respond to an analogue output to drive the second load device from 0 to 100 %, the rider will be able to chose auto or manual programming , from flat rides to hill climbs and circuit style programs .

The manual selection of effort will be achieved with a small push button on the handle bars ,there will be progressive indicators on the handle bars showing status of the program and remaining time left in the ride , and it will be displayed in kilojoules and to add insult to injury your effort at the end of the training session will be compared to how many candy bars or Big Mc burgers you just burned off on you training session .

So i am sorry if was a little vague but i thought i might need to brush up on my basic code writing skills and the first mole hill to get around is an accurate speed reference from a single prox input later to derive a method of ratios between the cyclist pedal speed and the back wheel speed .

Because of the lack of inputs just about every maths equation is going to be derived from these two single inputs there will be a lot of counting and comparing being done in the back ground .

And a small 6 inch panelview will be used to tell the rider were the program is up to with graphical and data type information .And the reason in am doing such a project is because i actually like the idea of modern automation and driving my self mad in the process and i don't like to give up on anything no matter what the cost .

MY manta is never give up. and if you need proof of my mental state i can send you email pictures of the status of this project in my garage .

So on a final note if this only serves to confuse the picture i am very sorry, for any confusion made.

I actually Own a couple of plc,s and like i have been stating , code writing i am weakest at , my programs usually look like a hard wired attempt there's nothing fancy or stylish about how i write .

I know i have been vague about where i am going with this because i would have dribbled on far to long and you all would have written me off as a crazy with a lap top.

And granted i am starting to wonder if i have drooped a cog in trying to automate an exercise bike .

It would be far easer to go and buy the thing they are called amongst other things computrainer and sell for about $2400 US .

As for details it is rather simple i cant mount an encoder on the back wheel as it would get up to speeds of 6000 rpm , so a single prox input will do fine .

The other input is mounted near the rider, at the pedals and will monitor speed of the pedals , the maximum speed there is around 130 rpm

Things that will be measured include speed , distance , average power out put of the rider , there will be three load ranges hi med and low , there is a second load device that will respond to an analogue output to drive the second load device from 0 to 100 %, the rider will be able to chose auto or manual programming , from flat rides to hill climbs and circuit style programs .

The manual selection of effort will be achieved with a small push button on the handle bars ,there will be progressive indicators on the handle bars showing status of the program and remaining time left in the ride , and it will be displayed in kilojoules and to add insult to injury your effort at the end of the training session will be compared to how many candy bars or Big Mc burgers you just burned off on you training session .

So i am sorry if was a little vague but i thought i might need to brush up on my basic code writing skills and the first mole hill to get around is an accurate speed reference from a single prox input later to derive a method of ratios between the cyclist pedal speed and the back wheel speed .

Because of the lack of inputs just about every maths equation is going to be derived from these two single inputs there will be a lot of counting and comparing being done in the back ground .

And a small 6 inch panelview will be used to tell the rider were the program is up to with graphical and data type information .And the reason in am doing such a project is because i actually like the idea of modern automation and driving my self mad in the process and i don't like to give up on anything no matter what the cost .

MY manta is never give up. and if you need proof of my mental state i can send you email pictures of the status of this project in my garage .

So on a final note if this only serves to confuse the picture i am very sorry, for any confusion made.