[FONT=Arial, Helvetica, sans-serif][SIZE=-1]Hi guys,[/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif][SIZE=-1]

[/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif][SIZE=-1]Was wondering if someone could help me with some ladder logic on a Mitsubishi FX-64MR which we are using for running air compressors.[/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif][SIZE=-1]

[/SIZE][/FONT]

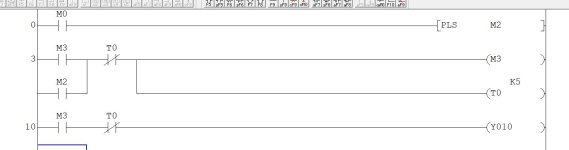

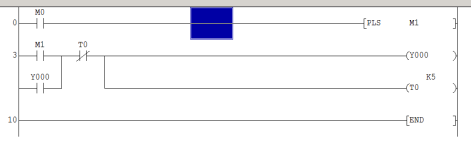

[FONT=Arial, Helvetica, sans-serif][SIZE=-1]The ladder logic is:[/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif][SIZE=-1]

[/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif][SIZE=-1] M0

[/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif][SIZE=-1]--| | --------------------[PLS M2][/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif][SIZE=-1]

[/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif][SIZE=-1] M2 T0

[/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif][SIZE=-1]--| |-----|-----|/|----|---------------(Y10)[/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif][SIZE=-1]--| |-----| |------|/|------(T0 K5)

[/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif][SIZE=-1] Y10 M2

[/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif][SIZE=-1]Apologies for the formatting above, hope it reads OK.

From what I've learnt, the T0 in this PLC is a non-retentive timer and will go to 1 when the timer is elapsed, and from the manual, K5 is 5 * 100ms so will go to 1 after 0.5s.

The problem I am having is the output coil Y10 never goes to 1 and I can't see what is wrong with the above? M0 is 1, and when taken to 0 and back to 1 still doesn't change Y10.

Do I need to change the K5 to something longer, is the previous application for a compressor which once is on, it stays on until it is told to turn off? The new air compressors aren't as such..

Hope someone can help, and thanks in advanced!

Kind regards,

Nathan

[/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif][SIZE=-1]

[/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif][SIZE=-1]Was wondering if someone could help me with some ladder logic on a Mitsubishi FX-64MR which we are using for running air compressors.[/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif][SIZE=-1]

[/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif][SIZE=-1]The ladder logic is:[/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif][SIZE=-1]

[/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif][SIZE=-1] M0

[/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif][SIZE=-1]--| | --------------------[PLS M2][/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif][SIZE=-1]

[/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif][SIZE=-1] M2 T0

[/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif][SIZE=-1]--| |-----|-----|/|----|---------------(Y10)[/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif][SIZE=-1]--| |-----| |------|/|------(T0 K5)

[/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif][SIZE=-1] Y10 M2

[/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif][SIZE=-1]Apologies for the formatting above, hope it reads OK.

From what I've learnt, the T0 in this PLC is a non-retentive timer and will go to 1 when the timer is elapsed, and from the manual, K5 is 5 * 100ms so will go to 1 after 0.5s.

The problem I am having is the output coil Y10 never goes to 1 and I can't see what is wrong with the above? M0 is 1, and when taken to 0 and back to 1 still doesn't change Y10.

Do I need to change the K5 to something longer, is the previous application for a compressor which once is on, it stays on until it is told to turn off? The new air compressors aren't as such..

Hope someone can help, and thanks in advanced!

Kind regards,

Nathan

[/SIZE][/FONT]

Last edited: