AutomationTechBrian

Lifetime Supporting Member

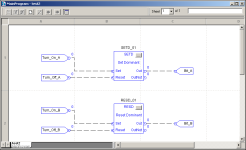

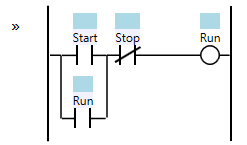

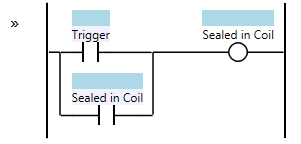

I figured out a solution to a vfd issue... at least in theory. Yaskawa has a program called Drive Works EZ that you can have PLC-type functions programmed into their industrial drives. It's function block programming. I just started working with it tonight, and I'm not seeing how to create a "latching" bit, with a set and reset, like we have in ladder. Most of these blocks are similar to other software programs, but I don't work with FB enough to think how to create a latching bit. Maybe there's a "standard" block that I could be looking for. I'm exploring this software tonight, but my available time is starting to run out.

This is an overview of how my control solution works:

Set bit if:

1. "Reverse" terminal closed

2. Zero Speed

3. Run Enable bit is high

Reset bit if:

1. "Reverse" terminal open

I realize the software is probably a little obscure to expect a reply... but you guys have surprised me in the past.

This is an overview of how my control solution works:

Set bit if:

1. "Reverse" terminal closed

2. Zero Speed

3. Run Enable bit is high

Reset bit if:

1. "Reverse" terminal open

I realize the software is probably a little obscure to expect a reply... but you guys have surprised me in the past.