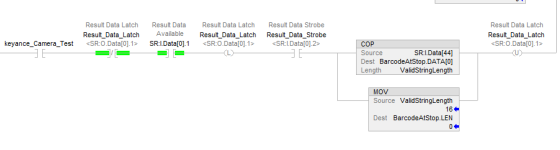

Is there anything inherently wrong with doing latching like this?

- Thread starter jg2024

- Start date

Similar Topics

Does the last octet mean anything?

Technically the network's address is 0, but why does it give you the option in the first place?

We had an enclosure unfortunately fill up entirely with water. We had a different components in there, a Dynamix 1444 Module and terminal base...

I've been looking at Ignition's platform and am impressed with its capabilities. The company that I've just started working at is using Citect...

I have been using Wonderware for the last five years ACD now at a place where review is mostly used. I would like to edit some pages and add...

I'm currently working on a FTV project and after putting 600+ hrs into Wonderware applications in the past year I realized two things... 1) I miss...