Hey guys,

I've a requirement that a two different PLC program should work in same system depending upon user input.

Consider Program A is used for a particular purpose which uses IO's in a different way and there is Program B is used for particular purpose which uses the same IO's but different operation from the program A.

We have tested both the programs separately and working as expected, Now we want a way to switch between the programs without using the PLC software to load different program.

I've tried to combine both PLC program to one file due to some multiple usage of same instruction above the limit I'm facing an issue with compiling.

So I'm here exploring different way to switch between two programs without any use of PLC soft (WPL Soft)

CPU- DVP12SE-11T

Software - WPL Soft and DCI soft for programming and communication.

Just curious that is there any way to load multiple PLC program to the memory card and just load a file depending upon selection through Modbus communication from software (Custom).

I've a requirement that a two different PLC program should work in same system depending upon user input.

Consider Program A is used for a particular purpose which uses IO's in a different way and there is Program B is used for particular purpose which uses the same IO's but different operation from the program A.

We have tested both the programs separately and working as expected, Now we want a way to switch between the programs without using the PLC software to load different program.

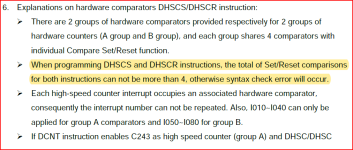

I've tried to combine both PLC program to one file due to some multiple usage of same instruction above the limit I'm facing an issue with compiling.

So I'm here exploring different way to switch between two programs without any use of PLC soft (WPL Soft)

CPU- DVP12SE-11T

Software - WPL Soft and DCI soft for programming and communication.

Just curious that is there any way to load multiple PLC program to the memory card and just load a file depending upon selection through Modbus communication from software (Custom).