It's not necessarily a good thing or a bad thing. It depends on the circumstance. In most cases it probably doesn't matter. In some cases it does.

Lets think though a few different situations. Would having a processor that runs twice as fast make your program perform better? The periodic and event driven tasks usually wouldn't be better. They would start executing at the same time, but would run through quicker, but I don't think that makes them better. The continuous tasks would execute more frequently. Would that make them function better? Maybe only parts of the continuous task provides better functionality by running faster. If there are parts that run better by running more frequently, then we can take them out of the continuous task and put them in a periodic task and run them at the appropriate frequency.

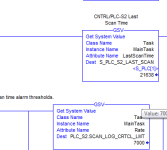

For example, how frequently does the logic that runs a motor starter and interlock need to run? Once every 10 seconds? Once every second? 10 times per second? As fast as possible? If you think as fast as possible is correct, but that turns out to be one every second to second and a half. I'd disagree. I like to see my downstream interlocks knock down the upstream equipment faster than that. I would say we should take these parts out of the continuous task that perform better by running more frequently and put them in a continuous task and run them at the period they need. If we have more processing time available, we could reduce the period further to make this specific program work "better". If your continuous task is completing in less than 1/10 of a second and nothing is in the continuous task that would preform better by running more frequently, then having a continuous task that runs more frequently, performance wise, it probably doesn't matter. And if it doesn't matter, running in a continuous is also not better. Its not bad either.

On the other hand, lets say we have a program that is running a bubble sort on an array of 5000 values. If this run in a periodic task, it could take a very long time to complete. If we ran in it a continuous task, it would complete much faster. If it was the only thing in the continuous task, it would complete even faster.

Of course if we had a system that would perform better by running the program faster, we could spend time optimizing the system, or we could by a faster processor (if there is one). Which is better or the other bad idea? It depends on the circumstances.

AB recommends that when designing the Plant PAX systems that we only using periodic and event driven tasks, and have the processor usage less than 50%. But then after the customer get the system, it is OK for him to make changes so long as they keep it under 75%. I see two benefits of doing things this way. 1) it is easy to see that your tasks are getting completed at the rate they need to run. 2) it is easy to see when your system is becoming loaded, and may need adjustment or upgrades. Even though most of the ControlLogix systems aren't Plant PAX system, their recommendations hold value.

Like most things in life, when achieving one goal, other things are effected. If we don't understand these other effects, we may make the right decision anyway. But I figure that's the difference between competence and lucky.