Jonas Zimmer

Member

Hey guys, new to dealing with major plc faults and wanted to run this past the pros.

I got a major fault.

Description:

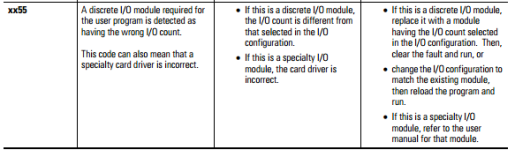

Discrete I/o module in slot 6 which is required for the user program is detected as having the wrong I/o count. This could also mean that a specialty card driver is incorrect.

The card in slot 6 is a 4 input analogue card.

Bad card? It's been operating for about 5-7 years. I am not sure what the specialty card driver is incorrect message means...

Major error s:6 = 655h

Last major error s:54 = 655h

Any help is appreciated.

Thanks

I got a major fault.

Description:

Discrete I/o module in slot 6 which is required for the user program is detected as having the wrong I/o count. This could also mean that a specialty card driver is incorrect.

The card in slot 6 is a 4 input analogue card.

Bad card? It's been operating for about 5-7 years. I am not sure what the specialty card driver is incorrect message means...

Major error s:6 = 655h

Last major error s:54 = 655h

Any help is appreciated.

Thanks