drbitboy

Lifetime Supporting Member

> Sodium Chloride has listed solubility of 35.7g per 100ml water at 0 Celsius and 39.12 at 100 Celsius.

I was surprised that the temperature coefficient is so small.

An alternate expession of solubility is the saturated salt percentage by weight (~26%+) and the specific gravities of brine (~1.2) and salt (~2.2), which is what are needed for the weighing formula; but I don't think they are useful here.

Does the undissolved salt turn into cake (loss of surface area)? Or is it sitting on a gravel bed or similar and the fresh water comes in from the bottom which minimizes caking?

Any, I think OceanSoul's solution is the right one. I suspect this need be neither a continuous nor even a frequent measurement: it's a bang-bang control to determine when to add salt.

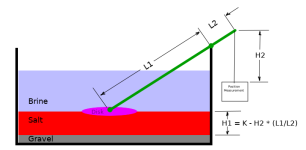

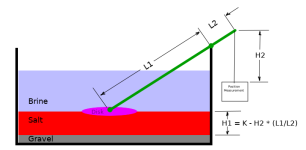

With the yoyo, I would be concerned about brine in the device. One way to get around that would be the simple-minded idea sketched below, which may or may not work, but which lets the designer control the materials submerged in brine. It would need a PLC or similar to drive a motor to lift the disk regularly and when salt was added. Also, the H2 measurement has a small cosine-near-zero-degrees error, but maybe that is replaced with a prox to indicate when to add salt.

Just too much time on my hands, to go along with all the time spent on this thread!

I was surprised that the temperature coefficient is so small.

An alternate expession of solubility is the saturated salt percentage by weight (~26%+) and the specific gravities of brine (~1.2) and salt (~2.2), which is what are needed for the weighing formula; but I don't think they are useful here.

Does the undissolved salt turn into cake (loss of surface area)? Or is it sitting on a gravel bed or similar and the fresh water comes in from the bottom which minimizes caking?

Any, I think OceanSoul's solution is the right one. I suspect this need be neither a continuous nor even a frequent measurement: it's a bang-bang control to determine when to add salt.

With the yoyo, I would be concerned about brine in the device. One way to get around that would be the simple-minded idea sketched below, which may or may not work, but which lets the designer control the materials submerged in brine. It would need a PLC or similar to drive a motor to lift the disk regularly and when salt was added. Also, the H2 measurement has a small cosine-near-zero-degrees error, but maybe that is replaced with a prox to indicate when to add salt.

Just too much time on my hands, to go along with all the time spent on this thread!

Last edited: