Hi All,

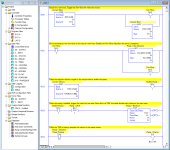

Looking for advice on programming MicroLogix 1400 with RSLogix500.

Basically, I have a client who requested I make a "simple" program that runs 5 pumps with 24 (every hour) for the day to turn on each pump at certain time for X amount of minutes. Sounds simple right?

Here is the catch based on that description:

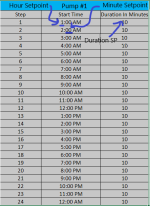

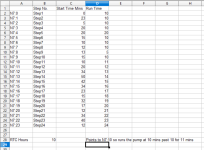

1x setpoint for Pump 1 Step 1 Enable (on/off boolean)

1x setpoint for Pump 1 Step 1 Start Hour (example: 10:xx AM)

1x setpoint for Pump 1 Step 1 Start Minutes (example: 10:30AM)

1x Setponit for Pump 1 Step 1 Run Duration (example: 5 minutes runtime)

Total: 4x setpoints

There are 24 steps for each pump. 24*4=96 setpoints for 1 pump.

There are 5 Pumps in total 5*96= 480 setpoints

Seems like a lot of ladder logic for such simple programming and easy to make a mistake along the way. I looked into sequencer block on RSLogix500, but it is kind of confusing. Is there a simpler way to programming this?

If you can help please let me know!

Thanks in advance!

Looking for advice on programming MicroLogix 1400 with RSLogix500.

Basically, I have a client who requested I make a "simple" program that runs 5 pumps with 24 (every hour) for the day to turn on each pump at certain time for X amount of minutes. Sounds simple right?

Here is the catch based on that description:

1x setpoint for Pump 1 Step 1 Enable (on/off boolean)

1x setpoint for Pump 1 Step 1 Start Hour (example: 10:xx AM)

1x setpoint for Pump 1 Step 1 Start Minutes (example: 10:30AM)

1x Setponit for Pump 1 Step 1 Run Duration (example: 5 minutes runtime)

Total: 4x setpoints

There are 24 steps for each pump. 24*4=96 setpoints for 1 pump.

There are 5 Pumps in total 5*96= 480 setpoints

Seems like a lot of ladder logic for such simple programming and easy to make a mistake along the way. I looked into sequencer block on RSLogix500, but it is kind of confusing. Is there a simpler way to programming this?

If you can help please let me know!

Thanks in advance!