Mas01

Member

Hi, this code refers to a Mitsubishi Q68AD-G card.

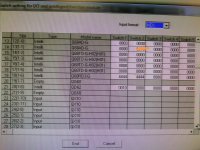

Ch 06 was previously a SPARE channel, but I want to use it as a 0-5vDC input (D33). To this end, I updated the I/O assignment (switch 2) from the default 0000h to 0030h, as per the module spec. I then wrote to the PLC. Then I put 0.5Vdc onto that channel, but the value stayed at zero. Anyone know why? E.g. do I need to do more configuring of that channel in GX developer? Thanks

Ch 06 was previously a SPARE channel, but I want to use it as a 0-5vDC input (D33). To this end, I updated the I/O assignment (switch 2) from the default 0000h to 0030h, as per the module spec. I then wrote to the PLC. Then I put 0.5Vdc onto that channel, but the value stayed at zero. Anyone know why? E.g. do I need to do more configuring of that channel in GX developer? Thanks

Last edited: