Mas01

Member

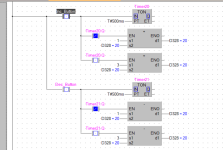

On our PLC we've got a HMI where the operator can enter a target rotor speed in RPM. When target speed is enabled, M70 = TRUE. Then the operator presses a "raise speed" or "lower speed" physical button to increase the rotor speed. I THINK the idea is that the "raise speed" button is inhibited when the target speed is reached.

From the code, can anyone work out what is going on? Operator tells me that 'enable target speed has never worked properly - or they're not sure how to use it, and prefer to reach the target speed manually.

From the code, can anyone work out what is going on? Operator tells me that 'enable target speed has never worked properly - or they're not sure how to use it, and prefer to reach the target speed manually.