Hi Lancie,

I did some simulation test with the information you gave me. Here's what happens:

My HMI button are configured as you thought, which is "Toggle" Maintained Contacts.

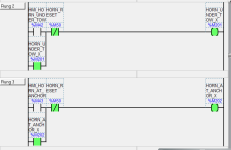

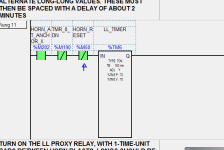

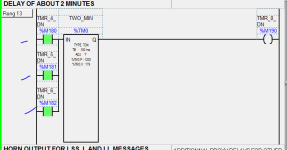

From my simulation test, I can see that the 2 minute Timer can reset each time one of the different signals are trigered. It goes back to zero up until the first message has been sent.

My main problem now, is for the MANUAL SIGNAL PUSH BUTTON that is set to Momentary Contact on the HMI. We want to be able to send one time manual messages (they won't need to be stored in memory). So, I think I understand what you are describing in your last post when praising the benefits of being able to have control over some setup memory bits that gives the ability to cancel a message, if another button is pressed in the middle of an ongoing sequence.

I ran first on that problem testing the MANUAL SIGNAL PUSH BUTTON with a Momentary Contact; as soon as the button is pressed then released during an ongoing message (for example LSS in the background, then I press the Manual Push), the ongoing message do not stop, it just repeats again reseting all timers (because my HMI button for message on the HMI are set to Maintained Contact).

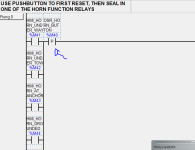

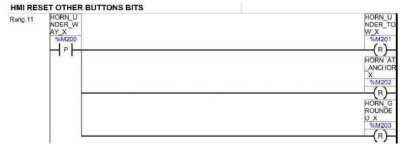

So my current attempt is to add a reset for other bits when the Manual Signal Push Button is pressed.

From what I understand, using a memory bit that indicates an ongoing message is being sent or in queue for another transmission after the 2 min timer limit has been reached, would allow me to keep the lights of a Momentary Contact Button on the HMI screen, just keeping the memory bit active? But then could it be disabled by pressing again the same button like a Maintained Contact type? Should I add an OFF BUTTON on the HMI or this would be a waste of time in my case and I should use several bit reset like I did so far?

Much appreciated,

Alex

I did some simulation test with the information you gave me. Here's what happens:

My HMI button are configured as you thought, which is "Toggle" Maintained Contacts.

Lancie said:The problem is that if ANOTHER horn button is pressed before the 2-minute Pause from the LAST horn function, then the way you had it before, there was nothing to reset the timers.

From my simulation test, I can see that the 2 minute Timer can reset each time one of the different signals are trigered. It goes back to zero up until the first message has been sent.

My main problem now, is for the MANUAL SIGNAL PUSH BUTTON that is set to Momentary Contact on the HMI. We want to be able to send one time manual messages (they won't need to be stored in memory). So, I think I understand what you are describing in your last post when praising the benefits of being able to have control over some setup memory bits that gives the ability to cancel a message, if another button is pressed in the middle of an ongoing sequence.

I ran first on that problem testing the MANUAL SIGNAL PUSH BUTTON with a Momentary Contact; as soon as the button is pressed then released during an ongoing message (for example LSS in the background, then I press the Manual Push), the ongoing message do not stop, it just repeats again reseting all timers (because my HMI button for message on the HMI are set to Maintained Contact).

So my current attempt is to add a reset for other bits when the Manual Signal Push Button is pressed.

From what I understand, using a memory bit that indicates an ongoing message is being sent or in queue for another transmission after the 2 min timer limit has been reached, would allow me to keep the lights of a Momentary Contact Button on the HMI screen, just keeping the memory bit active? But then could it be disabled by pressing again the same button like a Maintained Contact type? Should I add an OFF BUTTON on the HMI or this would be a waste of time in my case and I should use several bit reset like I did so far?

Much appreciated,

Alex

Last edited: