Hello, first of all thank you for reading this post. I am pretty new at PLC programming!

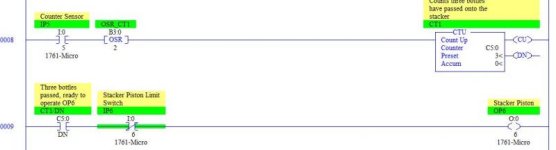

I have a problem with a CTU and the reset function. You should have the rungs in attachment.

It's a bottling plant. The packer at the end of the plant needs to wait 3 bottles before activating the stacker.

When the stacker is activated, I thought of resetting the CTU to 0 "zero", but the CTU resets only to 1 then counts 2-3.

So basically, 3 bottles are counted the first time and from then, only two!

Am I doing anything wrong? Is there a more standardized way of programming a bottle stacker?

Much appreciated! :site:

I have a problem with a CTU and the reset function. You should have the rungs in attachment.

It's a bottling plant. The packer at the end of the plant needs to wait 3 bottles before activating the stacker.

When the stacker is activated, I thought of resetting the CTU to 0 "zero", but the CTU resets only to 1 then counts 2-3.

So basically, 3 bottles are counted the first time and from then, only two!

Am I doing anything wrong? Is there a more standardized way of programming a bottle stacker?

Much appreciated! :site: