Hi,

I am very confused this time, there is no other way but to consult. This is out of topic, but please spare me.

I am currently troubleshooting a fire alarm system that I suspect is having a ground fault (sigh). I am researching on how to check which lead/ conductor is faulty. I have read on one article that I need to take out all wiring from the electronic panel & bring out my ohmmeter, set it to the highest continuity & start reading between each lead/ conductor vs. a given ground. Considering correct electrical practice have been made during installation, it is safe to consider the electrical conduit as a ground.

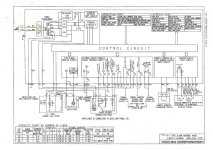

Here's where I am very much confused. I have known that as a "good" electrical practice, say for a single phase installation, the neutral line must be connected to a ground (see attached page). When a fault appears, it will not harm any component or human in any instances, it will simply blow the fuse or trip the breaker. Given this statement, if I follow what the article above suggests, then I will surely read multiple continuity to ground.

I am really confused please help me.

I am very confused this time, there is no other way but to consult. This is out of topic, but please spare me.

I am currently troubleshooting a fire alarm system that I suspect is having a ground fault (sigh). I am researching on how to check which lead/ conductor is faulty. I have read on one article that I need to take out all wiring from the electronic panel & bring out my ohmmeter, set it to the highest continuity & start reading between each lead/ conductor vs. a given ground. Considering correct electrical practice have been made during installation, it is safe to consider the electrical conduit as a ground.

Here's where I am very much confused. I have known that as a "good" electrical practice, say for a single phase installation, the neutral line must be connected to a ground (see attached page). When a fault appears, it will not harm any component or human in any instances, it will simply blow the fuse or trip the breaker. Given this statement, if I follow what the article above suggests, then I will surely read multiple continuity to ground.

I am really confused please help me.