Ron Beaufort

Lifetime Supporting Member

... so you don't like the RG bit? ...

Greetings Peter and all,

I’m still trying to get in enough time to work on this thread ... one thing that I would like to add:

Peter said:

I still haven’t had time to go over all of this in detail so maybe I’m missing something here ... but ...

I don’t think that the RG bit is flawed, Peter ... at least not on the SLC ... again, I don’t have a MicroLogix 1500 handy to experiment with ... but I just tried this experiment on an SLC-5/04 to confirm my thoughts ...

in a completely new program (without your simulator, etc.) set up two identical PIDs ... of course you’ll need two separate control blocks ... use a separate CV for each PID ... but use the !SAME! PV ... enter the !SAME! SP value for each PID ... in fact, go ahead and include a rung which will constantly MOV the !SAME! Setpoint into each PID ... what we’re obviously trying to do here is have two identical PIDs ... both looking at the same PV and trying to maintain the same setpoint ...

but for one PID, leave the RG bit OFF ... the Kc and the Ti entries will each have only !ONE! decimal point ... enter 2.0 for the Kc and 2.0 for the Ti ...

note: the RG bit doesn’t affect the Td (derivative) operation in any way ... ... (at least according to the book ... and I really think that it’s correct on this issue) ... specifically, the Td setting ALWAYS has two decimal places regardless of the RG bit setting ... let’s just leave Td set at 0.00 for now ...

for the other PID, turn the RG bit ON ... the Kc and the Ti entries will now each have !TWO! decimal points ... enter 2.00 for the Kc and 2.00 for the Ti ...

so even with the extra decimal point of resolution, we still should have the exact same tuning for each of the PIDs ...

now manually force the PV to equal the setpoint ... and set up a trend to simultaneously graph the response of !BOTH! of the PIDs ... and finally put the thing in the Run mode ... let the graph run for a minute or so to get a base line ... next change the setpoint of the two PIDs ... if you’ve set up the MOV rung that I mentioned earlier, then both of the PIDs should change at exactly the same time ...

and I believe that you’ll find that both PIDs will give EXACTLY the same response ... REGARDLESS of whether the RG bit is turned OFF or turned ON ... specifically, since both PIDs are looking at the exact same PV (input) and giving the exact same CVs (outputs), then we could surmise that the RG bit is NOT adversely affecting the response of either PID ... the CVs should be perfectly superimposed regardless of what you do to the PVs and the SPs ...

so what good is the RG bit anyway? ... it just allows us a little more resolution when we get ready to enter our Kc (Proportional) and Ti (Integral) settings ... and more resolution is always a good thing ...

I know it will be awhile before you get to work on this again ... but if you do get to run this little experiment on the MicroLogix 1500 and obtain any different results, please let me know ... but based on what I’ve seen on the SLC platform, I’d say that there is no flaw in the RG bit ... MAYBE there is on the MicroLogix 1500 ... but are you sure that everything else was set up the same when you made your observations? ... specifically, are you sure that you altered the original Kc and Ti entries to compensate for the extra decimal point? ... the entries will NOT automatically alter themselves when you turn the RG bit on or off ...

Greetings Peter and all,

I’m still trying to get in enough time to work on this thread ... one thing that I would like to add:

Peter said:

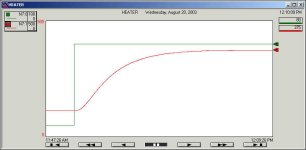

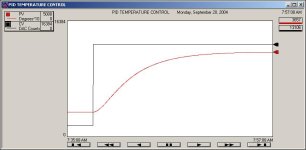

The RG bit is flawed!!!!!! Compare this trend with the RG bit set and the trend without the RG bit set in the first post. You can see the trend WITHOUG the RG bit set looks much better except for the coarse control.

I still haven’t had time to go over all of this in detail so maybe I’m missing something here ... but ...

I don’t think that the RG bit is flawed, Peter ... at least not on the SLC ... again, I don’t have a MicroLogix 1500 handy to experiment with ... but I just tried this experiment on an SLC-5/04 to confirm my thoughts ...

in a completely new program (without your simulator, etc.) set up two identical PIDs ... of course you’ll need two separate control blocks ... use a separate CV for each PID ... but use the !SAME! PV ... enter the !SAME! SP value for each PID ... in fact, go ahead and include a rung which will constantly MOV the !SAME! Setpoint into each PID ... what we’re obviously trying to do here is have two identical PIDs ... both looking at the same PV and trying to maintain the same setpoint ...

but for one PID, leave the RG bit OFF ... the Kc and the Ti entries will each have only !ONE! decimal point ... enter 2.0 for the Kc and 2.0 for the Ti ...

note: the RG bit doesn’t affect the Td (derivative) operation in any way ... ... (at least according to the book ... and I really think that it’s correct on this issue) ... specifically, the Td setting ALWAYS has two decimal places regardless of the RG bit setting ... let’s just leave Td set at 0.00 for now ...

for the other PID, turn the RG bit ON ... the Kc and the Ti entries will now each have !TWO! decimal points ... enter 2.00 for the Kc and 2.00 for the Ti ...

so even with the extra decimal point of resolution, we still should have the exact same tuning for each of the PIDs ...

now manually force the PV to equal the setpoint ... and set up a trend to simultaneously graph the response of !BOTH! of the PIDs ... and finally put the thing in the Run mode ... let the graph run for a minute or so to get a base line ... next change the setpoint of the two PIDs ... if you’ve set up the MOV rung that I mentioned earlier, then both of the PIDs should change at exactly the same time ...

and I believe that you’ll find that both PIDs will give EXACTLY the same response ... REGARDLESS of whether the RG bit is turned OFF or turned ON ... specifically, since both PIDs are looking at the exact same PV (input) and giving the exact same CVs (outputs), then we could surmise that the RG bit is NOT adversely affecting the response of either PID ... the CVs should be perfectly superimposed regardless of what you do to the PVs and the SPs ...

so what good is the RG bit anyway? ... it just allows us a little more resolution when we get ready to enter our Kc (Proportional) and Ti (Integral) settings ... and more resolution is always a good thing ...

I know it will be awhile before you get to work on this again ... but if you do get to run this little experiment on the MicroLogix 1500 and obtain any different results, please let me know ... but based on what I’ve seen on the SLC platform, I’d say that there is no flaw in the RG bit ... MAYBE there is on the MicroLogix 1500 ... but are you sure that everything else was set up the same when you made your observations? ... specifically, are you sure that you altered the original Kc and Ti entries to compensate for the extra decimal point? ... the entries will NOT automatically alter themselves when you turn the RG bit on or off ...