Peter Nachtwey

Member

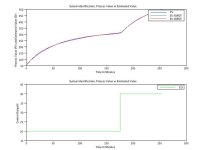

The default should look like this

The graphical response should be almost perfect. I know and now you know the magic formulas. I should start a new thread for those that want to play along and ask questions.

Oh, one more thing. I made a Scilab directory in my Documents folder. You need to change the current directly to where ever you stored the Scilab file.

The scilab.start file is in the etc directory.

C:\Program Files\scilab-5.2.2\etc

I added this line at the bottom of the scilab.start file just before clear ans.

chdir "c:\Documents and Settings\Peter\My Documents\Scilab\"

Obviously you need to use your user name.

To make the graphs use the export feature and export .png or .jpg files.

The Scilab script can be copied and pasted in between code /code tags

The graphical response should be almost perfect. I know and now you know the magic formulas. I should start a new thread for those that want to play along and ask questions.

Oh, one more thing. I made a Scilab directory in my Documents folder. You need to change the current directly to where ever you stored the Scilab file.

The scilab.start file is in the etc directory.

C:\Program Files\scilab-5.2.2\etc

I added this line at the bottom of the scilab.start file just before clear ans.

chdir "c:\Documents and Settings\Peter\My Documents\Scilab\"

Obviously you need to use your user name.

To make the graphs use the export feature and export .png or .jpg files.

The Scilab script can be copied and pasted in between code /code tags

Last edited: