dginbuffalo

Member

Hello,

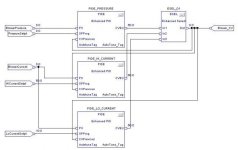

I have a enhanced PID funning in a function block on a Compactlogic L35 processor. it is running to a pressure SP but if the current gets too high or too low i need to stop the CV from updating. The low and high limits will always be calculating depending on what pressure the unit is at. Any suggestions on the best way to do this? i was thinking about a LES and GRT then on the CV output that i would turn on and off if current was hitting a certain level. or changing the CV out low and high limits on the fly. Ideas?

I have a enhanced PID funning in a function block on a Compactlogic L35 processor. it is running to a pressure SP but if the current gets too high or too low i need to stop the CV from updating. The low and high limits will always be calculating depending on what pressure the unit is at. Any suggestions on the best way to do this? i was thinking about a LES and GRT then on the CV output that i would turn on and off if current was hitting a certain level. or changing the CV out low and high limits on the fly. Ideas?