davidgeorge212

Member

Q I am brand new to plc's but I had a couple courses in college. Any help in detail would be much appreciated.

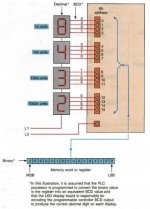

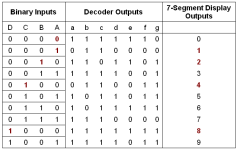

What I would like to do is make a 7 segment display and have my plc tell it what numbers to display based on a timer or count down. I've read that you can hook up each of the seven segments to their own output port on the plc. I understand how that can now make any number based on which outputs are energized. What I don't understand is how or what the best way to tell the plc is to turn on those outputs. I would like to be a ble to push one start button which would start an internal 30 second count timer and simultaneously have the outputs light up the numbers as it counts down (9, 8, 7, 6, etc.)

I hope some of what I explained makes since because I really would like to know how I can do this. I also hope that what I want do is as easy as I think it should be. Do you think it's doable?

Thanks David

What I would like to do is make a 7 segment display and have my plc tell it what numbers to display based on a timer or count down. I've read that you can hook up each of the seven segments to their own output port on the plc. I understand how that can now make any number based on which outputs are energized. What I don't understand is how or what the best way to tell the plc is to turn on those outputs. I would like to be a ble to push one start button which would start an internal 30 second count timer and simultaneously have the outputs light up the numbers as it counts down (9, 8, 7, 6, etc.)

I hope some of what I explained makes since because I really would like to know how I can do this. I also hope that what I want do is as easy as I think it should be. Do you think it's doable?

Thanks David