Mickey is exactly right: the PLC-5 PID instruction needs to be executed at the same interval as is programmed into its Loop Update Time parameter. This is described in the Instruction Set Reference (1785-RM001 pages 14-10, 14-16, 14-26. etc) and the Help file and in every PID lecture, article, quickstart, and example. The ladder logic examples begin on page 14-30 of that manual.

I have seen plenty of systems like this that essentially work by coincidence: the programmers managed to tune the loops even though the Update time (configured in the PID instruction data block) and the execution time (dependent on the scantime because they are executing the PID unconditionally) are different. Those programs work OK until there's an upgrade or expansion and the execution rate of the routine changes.

This especially bites programmers who had experience with the TI-505 system, which treated PID like a set of configurable loop controllers.

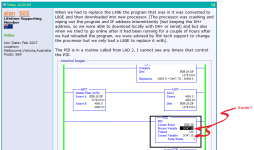

Because this is in LAD2, the default RLL routine for A-B controllers since the 1980s, it is surely not configured to be executed by a Selectable Timed Interrupt (STI).

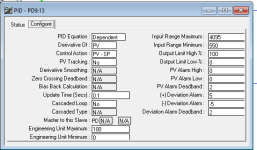

Another PLC-5 specific thing is that this PID instruction is using the "PD" datatype, which was introduced with the PLC-5 Enhanced controllers. The older PLC-5/15 and /25 Classic controllers used an Integer data file to store the parameters and data for the instruction, and you can retain that method in an Enhanced controller if you wish. PD-based instructions will execute every scan when programmed un-conditionally like this, while an N-file based instruction needs to see a rung condition false->true transition and would never have worked. This is noted in the 1785-RM001 manual on page 14-12.

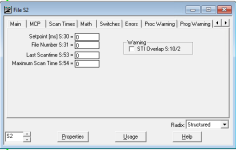

The best way to resolve this problem is to run the application on a PLC-5/40, even for a short period of time, and capture the Scantime of the LAD2 routine. Then use that to set up Timers or an STI to run this PID code at the same interval.

It still probably won't be actually correct, but it should get the loops working similar to how they worked in the PLC-5/40.