drbitboy

Lifetime Supporting Member

1) It sounds like this program is not yours, you know basically bupkis about it, but you want to port it from a failed or failing 1785-L40E to a 1785-L80E.

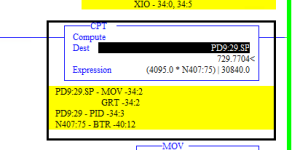

2) That PID is not scheduled correctly; that may not be the primary problem right now, but let's speculate:

2.1) From various info found via the The Google it appears that a PLC-5 Logic Scan Time can be anywhere from no faster than 6ms to 500ms and up. I think my brother told me that PLC-5 logic is interpreted, not compiled; that and the age of the PLC-5 line makes those numbers seem reasonable.

2.1.1) So the 0.1s (100ms) Loop Update Time in the PID configuration menu is not unbelievable, and may actually be correct, even if by luck (or coincidence, as @Ken Roach said), or it may have been empirically determined via the "I watched S:53 and S:54 online for a few minutes on the -L40E" method, perhaps with an unconsummated "I'll fix it later" on the side.

2.2) We don't know your process, but the Ti and Td tuning time constants are 10 and 3 minutes, so this process is slow, in which case an estimate determined via the method in (2.1.1), while something less than best practice, could certainly produce workable results.

2.3) My point is that any error in the entered Loop Update Time, which error is almost certainly no more than a factor of 15, is not so big it could not be absorbed and corrected for in those large-ish tuned values of Ti and Td, assuming the process was manually tuned at some point.

So while tuning, and especially the Loop Update Time, is suspect and should be done correctly at some point, I would put a pin in that line of investigation for now, and look into the duplicate declaration of the PV and CV first.

2) That PID is not scheduled correctly; that may not be the primary problem right now, but let's speculate:

2.1) From various info found via the The Google it appears that a PLC-5 Logic Scan Time can be anywhere from no faster than 6ms to 500ms and up. I think my brother told me that PLC-5 logic is interpreted, not compiled; that and the age of the PLC-5 line makes those numbers seem reasonable.

2.1.1) So the 0.1s (100ms) Loop Update Time in the PID configuration menu is not unbelievable, and may actually be correct, even if by luck (or coincidence, as @Ken Roach said), or it may have been empirically determined via the "I watched S:53 and S:54 online for a few minutes on the -L40E" method, perhaps with an unconsummated "I'll fix it later" on the side.

2.2) We don't know your process, but the Ti and Td tuning time constants are 10 and 3 minutes, so this process is slow, in which case an estimate determined via the method in (2.1.1), while something less than best practice, could certainly produce workable results.

2.3) My point is that any error in the entered Loop Update Time, which error is almost certainly no more than a factor of 15, is not so big it could not be absorbed and corrected for in those large-ish tuned values of Ti and Td, assuming the process was manually tuned at some point.

So while tuning, and especially the Loop Update Time, is suspect and should be done correctly at some point, I would put a pin in that line of investigation for now, and look into the duplicate declaration of the PV and CV first.

Last edited: