Mudassir,

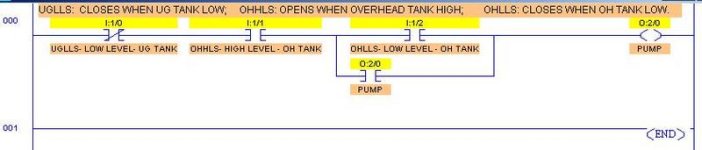

I do not understand why you need the >=1 comparison after the 3rd switch NC OHLLS. It seems like you could wire it directly to the NOT AND function block.

Whether or not it is correct depends on the definition of the 3 switches (when they are open and when they are closed). Each switch could be physically set up to be either normally open or normally closed. Your logic must be based on the actual switches.

I do not understand why you need the >=1 comparison after the 3rd switch NC OHLLS. It seems like you could wire it directly to the NOT AND function block.

Whether or not it is correct depends on the definition of the 3 switches (when they are open and when they are closed). Each switch could be physically set up to be either normally open or normally closed. Your logic must be based on the actual switches.

Last edited: