nguyenxuanphu

Member

Hi ! Everybody !

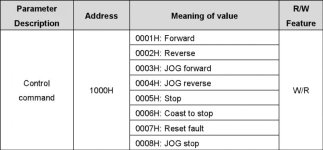

Please..help me about communication between S7 1200 and inverter or any varispeed inverter had MODBUS support by module CM1241 MODBUS RTU RS485...!

I try to do that but not success !

Thank you very much !

Please..help me about communication between S7 1200 and inverter or any varispeed inverter had MODBUS support by module CM1241 MODBUS RTU RS485...!

I try to do that but not success !

Thank you very much !