AutomationTechBrian

Lifetime Supporting Member

I went on a service call yesterday for a Micrologix 1500. An output wasn't activating and they wanted to know what was hanging it up. It was a small program with one main ladder and about 50 rungs... it took maybe 30 minutes to get setup, hooked-up, uploaded, and the missing input found. Wanting to make the most of our time, my customer asked if there was anything I could do to alleviate an annoying problem. He said they've tried asking the guy who wrote the program how to fix the issue, but he has never replied to their request. Now he's retired and they've evidently given up trying to resolve the issue through him. It's an interesting problem that merits some thought, so I thought I'd share it with you guys to get your input.

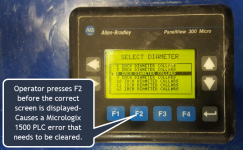

The machine uses a Panelview 300 micro to input the size settings. The operator pushes buttons to get to the selection screen, and when the correct selection is highlighted, he pushes F2 to load the selection. The problem comes with the lag-time between screens loading. The operator pushes F2 before the HMI is ready for the input, and it creates an error that freezes the PLC. I tried to get more specific information, but all they said was a guy had to come and hook up to the PLC and clear "a counter". I suspect it's a system thing because I didn't see any counters being used when I looked at the Counters-used-in-the-program file.

Evidently they can get a copy of the Micrologix and Panelview files from the machine builder if I think the issue can be fixed. Like I said, the original programmer has been retired for a while and hasn't responded to their previous requests. I was thinking about it while driving and wondered if this was something you folks have had to deal with. It's too vague to spend a lot of time on at this point, but it seems like it could be a common issue. Any thoughts?

The machine uses a Panelview 300 micro to input the size settings. The operator pushes buttons to get to the selection screen, and when the correct selection is highlighted, he pushes F2 to load the selection. The problem comes with the lag-time between screens loading. The operator pushes F2 before the HMI is ready for the input, and it creates an error that freezes the PLC. I tried to get more specific information, but all they said was a guy had to come and hook up to the PLC and clear "a counter". I suspect it's a system thing because I didn't see any counters being used when I looked at the Counters-used-in-the-program file.

Evidently they can get a copy of the Micrologix and Panelview files from the machine builder if I think the issue can be fixed. Like I said, the original programmer has been retired for a while and hasn't responded to their previous requests. I was thinking about it while driving and wondered if this was something you folks have had to deal with. It's too vague to spend a lot of time on at this point, but it seems like it could be a common issue. Any thoughts?