this is as much as I’ve got time for today ...

load the .RSS file into an SLC processor ... you may have to change the chassis size – and move the input and output modules to slots that match your (chassis) hardware ... make sure that the modules are “turned off” (not “enabled”) on the I/O tab of the Status File ... this lets you override the signals from the input module – so that you can manually type in any signal that you want it to “see” for experimental purposes ... also it lets you run the program without actually having the hardware present ...

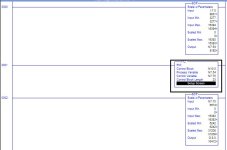

I’m simulating a temperature control loop which ranges from 0 to 500 degrees F ... at the beginning of the graph, I’ve entered a signal of 5898 at I:7.0 which equates to 100 degrees ... this is too cool for my setpoint of 250 degrees ...

important: how cool is “too cool” ? ... 100 divided by 500 equals 0.20 of full scale ... setpoint of 250 is 0.50 of full scale ... Error is 0.50 minus 0.20 equals 0.30 of full scale ... note that CV at this point of the graph is 0.30 of full scale ...

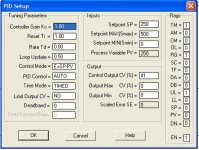

I have Kc set for 1.00 (entered as 100 at N10:3) ... so ... output of PID is 0.30 of full scale at these conditions ...

then I set the Integral action for 1.00 minutes per repeat (entered as 100 at N10:4) ... this makes the CV ramp upwards ...

then I set I:7.0 to 9831 to simulate an instantaneous rise in PV from 100 degrees to 250 degrees (now “on target” at setpoint) ... note that Integral action quits ramping the signal up ...

suggestion play with different settings at I:7.0 (or YOUR corresponding location) ... play with different settings for Kc and for Ti (skip Td for now) ... notice how PID responds – and try to work out WHY it acts the way that it does ...

note that you will NOT be able to “TUNE” the loop – since there is no actual feedback from the system – only what values you manually enter in for the PV signal ... but experimenting with this MAY be helpful as you try to figure out what’s going on ... with the PID ... wish I had more time to play ...

good luck with your project ...