Hello all.

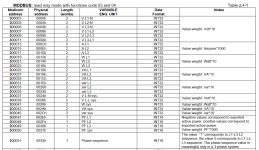

I am trying to read out the values from a Carlo Gavazzi EM340 energy analyzer via Modbus communication.

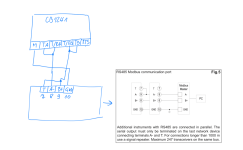

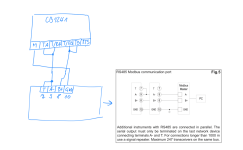

The S7-1200 PLC has the CB1241 module that is connected to the EM340 unit.

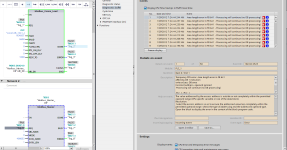

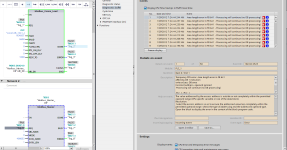

So I configured the Modbus_Comm_Load block and the Modbus_Master blocks (I've attached a picture of the configuration).

On the Modbus_Comm_Load block when I set the Req input to ''1'' the status Changes from #7000 #7002 and goes back to #7000 but I don't get a Done signal.

Nontheless I tried the Req input on the Modbus_Master block and then I get the following error in the diagnostic buffer of the PLC.

-

Temporary CPU error: Area length error in FB 641

affecting OB 1 execution

write access DB area

Incorrect address, operand ignored

Processing will continue (no OB processing)

PLC_1 / PLC_1

Internal address details: Caddr=16#00000CD0, area: DB area, addr: 0

-

And the Modbus Master block outputs the following error: #8281

This is from the help

16#8281

Negative acknowledgment when writing module

Check the input at the PORT parameter.

You can find more detailed information on error causes in the static parameters Send_P2P.WRREC.STATUS or Receive_P2P.WRREC.STATUS, and in the description of the SFB WRREC.

Any info what could be wrong? The Port number is correct, so I don't know what else to try...

Cheers

Aleix

I am trying to read out the values from a Carlo Gavazzi EM340 energy analyzer via Modbus communication.

The S7-1200 PLC has the CB1241 module that is connected to the EM340 unit.

So I configured the Modbus_Comm_Load block and the Modbus_Master blocks (I've attached a picture of the configuration).

On the Modbus_Comm_Load block when I set the Req input to ''1'' the status Changes from #7000 #7002 and goes back to #7000 but I don't get a Done signal.

Nontheless I tried the Req input on the Modbus_Master block and then I get the following error in the diagnostic buffer of the PLC.

-

Temporary CPU error: Area length error in FB 641

affecting OB 1 execution

write access DB area

Incorrect address, operand ignored

Processing will continue (no OB processing)

PLC_1 / PLC_1

Internal address details: Caddr=16#00000CD0, area: DB area, addr: 0

-

And the Modbus Master block outputs the following error: #8281

This is from the help

16#8281

Negative acknowledgment when writing module

Check the input at the PORT parameter.

You can find more detailed information on error causes in the static parameters Send_P2P.WRREC.STATUS or Receive_P2P.WRREC.STATUS, and in the description of the SFB WRREC.

Any info what could be wrong? The Port number is correct, so I don't know what else to try...

Cheers

Aleix