Hello everyone,

I just stumbled upon this site and it looks really interesting! This is my first post here.

I have never programmed PLCs before, therefore I am a complete beginner but I'm a quick learner. My first task is programming a m241 with ht eSoMachine v4.1 software. I have added the devices that will be used and made the majority of my POU.

However, I am confused with the memory mapping. I understand data types (bits, bytes, words, dwords etc) and I understand that the syntax is %MX, %MB etc. But from where can I start allocating memory? From what I understand there is also system reserved memory so it probably has a portion of memory reserved (bear in mind that I still haven't been able to read the entire self-service manual).

For example, I am measuring temperature over a sensor which is conncted to the analog input. I want to store that data inside a virtual variable so it can be accessed remotely.

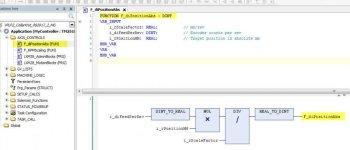

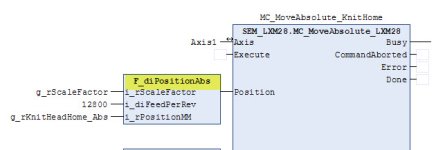

Also, function block instancing isn't completely clear to me. I made a function block which receives an INT from the sensor and converts it to REAL. When I insert the block inside POU, I get "???" over it. I don't understand what this "???" means or how I should remove it.

I realise I have a lot of knowledge gaps with PLC programming and I am grateful for any help you can provide.

Thanks in advance,

Tarik

I just stumbled upon this site and it looks really interesting! This is my first post here.

I have never programmed PLCs before, therefore I am a complete beginner but I'm a quick learner. My first task is programming a m241 with ht eSoMachine v4.1 software. I have added the devices that will be used and made the majority of my POU.

However, I am confused with the memory mapping. I understand data types (bits, bytes, words, dwords etc) and I understand that the syntax is %MX, %MB etc. But from where can I start allocating memory? From what I understand there is also system reserved memory so it probably has a portion of memory reserved (bear in mind that I still haven't been able to read the entire self-service manual).

For example, I am measuring temperature over a sensor which is conncted to the analog input. I want to store that data inside a virtual variable so it can be accessed remotely.

Also, function block instancing isn't completely clear to me. I made a function block which receives an INT from the sensor and converts it to REAL. When I insert the block inside POU, I get "???" over it. I don't understand what this "???" means or how I should remove it.

I realise I have a lot of knowledge gaps with PLC programming and I am grateful for any help you can provide.

Thanks in advance,

Tarik