Not too familiar with Siemens plc's and never used IO link before , but got an ifm starter kit, so some dumb questions coming up. I am good on relay logic, but bits n bytes are a bit of a struggle for me.

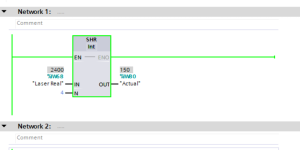

I have the S7 set up with the IO link master. It has a O5D150 laser sensor, connected on Port 1 and all good so far, all working and I have a " Raw data value, and using a shift register , I have a real value of 150 cm in my Tia Portal on %IW80

I then acquired a E30391 ifm display unit set the master port as "IO link In/Out 16/16 byte and connected it to Port 3 on the ifm master and disabled the two ports not in use. It supplied the Q address as 64 -79. All seems well, no errors on the program.

I uploaded here the "bytes info" from this display unit and my question (got there eventually ), is how do I get my real value on %IW80 onto this ifm screen. What blocks do I use and what format is the S7 output.

), is how do I get my real value on %IW80 onto this ifm screen. What blocks do I use and what format is the S7 output.

All the hardware is fine and working, I just need to know how to understand/decipher how the bytes info in the upload translates into Siemens output block.

eg say, I want a one line display with my real data from %IW80 displayed on a green colour with led 2 on.

I will try to work backwards to see if I can figure it out.

I have the S7 set up with the IO link master. It has a O5D150 laser sensor, connected on Port 1 and all good so far, all working and I have a " Raw data value, and using a shift register , I have a real value of 150 cm in my Tia Portal on %IW80

I then acquired a E30391 ifm display unit set the master port as "IO link In/Out 16/16 byte and connected it to Port 3 on the ifm master and disabled the two ports not in use. It supplied the Q address as 64 -79. All seems well, no errors on the program.

I uploaded here the "bytes info" from this display unit and my question (got there eventually

All the hardware is fine and working, I just need to know how to understand/decipher how the bytes info in the upload translates into Siemens output block.

eg say, I want a one line display with my real data from %IW80 displayed on a green colour with led 2 on.

I will try to work backwards to see if I can figure it out.