Mas01

Member

Hi,

Can anyone help me on this?

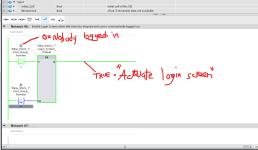

I want to implement a "screen lock" (HMI is KTP1200 Basic).

e.g. if the person who's logged in, leaves the screen idle for say 30 minutes, a simple screen lock page appears, with the text "Screen locked by <user>, Enter Password to continue".

When p/w is entered, the user is returned to the screen they were on prior to the screen locking. i.e. just like with your PC/laptop.

Do I need to change anything on this page? See pic.

Can anyone help me on this?

I want to implement a "screen lock" (HMI is KTP1200 Basic).

e.g. if the person who's logged in, leaves the screen idle for say 30 minutes, a simple screen lock page appears, with the text "Screen locked by <user>, Enter Password to continue".

When p/w is entered, the user is returned to the screen they were on prior to the screen locking. i.e. just like with your PC/laptop.

Do I need to change anything on this page? See pic.