ZestyMozzarella

Lifetime Supporting Member

Hi everyone, got a Siemens S7-1200 collecting data off one our furnace lines. I'm getting some interesting activity I'm working on cleaning up in our data collection. I was wanting to discuss what I'm seeing and whether anyone else has some thoughts to add to my ideas.

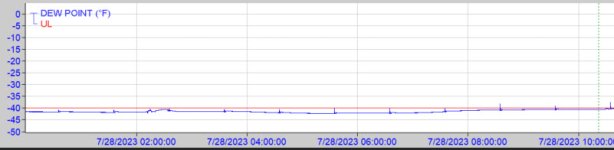

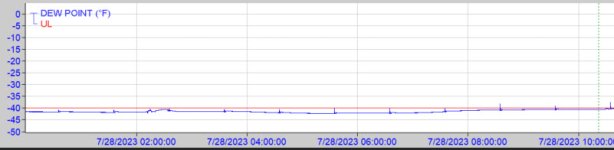

My first of two topics would be dew point collected and seen here:

Been collecting a 4-20mA signal from a hydrogen analyzer. This signal in a cyclical fashion seems to have a spike every so often. Doesn't appear to be happening at the LED screen and meter of the unit itself but it's recording in real time in the PLC which then sends over to IBA (a historical data collection unit). This could be happening in the PLC or the IBA data translation but usually in the past, it always come down to actually happening in the signal. Has anyone else ever witnessed such cyclical actions in signal collection and have any advice at what the culprit might be? Lines are shielded and ground attached, so I suspect it's not noise. I could establish a MAVG I suppose but as always, there is a fine line between MAVG and actual real time responsiveness that has to be respected. I'm asking the Analyzer company as well but figure individuals here may have run into similar issues and have some good perspective / advice on the matter.

My other issue is in speed collection seen here:

The speed on one tube collecting off a high resolution digital encoder via modbus TCP/IP appears to have a lot of noise at the start of a run but then mellows out. I do have an averaging function with a window size of about twenty, but that window would fill far faster than the time this takes to settle. Chain slip, tension issues, bridle issues...a lot of things can be ruled out because it doesn't happen once running after the first few minutes. I'm wondering if I'm seeing some noise in the motor circuit itself, the drives produced coming up to speed but the noise lasts for a little while before tapering off which I find odd since it's not abrupt like I would expect. Perhaps my resolution is too high...I'm thinking about lowering it since it's like a few thousand PPR and likely overkill on their defaults...collect some more data and see but curious if this speed trend sparks any obvious insight from other individuals in the field.

The signals on mA are set to (weak cycle) for smoothing as well...I've considering upping these a little to perhaps handle some noise but I need to respect real time circuit sensitivity to actual change as well.

As always thank you and appreciate everyone's perspective and feedback!

My first of two topics would be dew point collected and seen here:

Been collecting a 4-20mA signal from a hydrogen analyzer. This signal in a cyclical fashion seems to have a spike every so often. Doesn't appear to be happening at the LED screen and meter of the unit itself but it's recording in real time in the PLC which then sends over to IBA (a historical data collection unit). This could be happening in the PLC or the IBA data translation but usually in the past, it always come down to actually happening in the signal. Has anyone else ever witnessed such cyclical actions in signal collection and have any advice at what the culprit might be? Lines are shielded and ground attached, so I suspect it's not noise. I could establish a MAVG I suppose but as always, there is a fine line between MAVG and actual real time responsiveness that has to be respected. I'm asking the Analyzer company as well but figure individuals here may have run into similar issues and have some good perspective / advice on the matter.

My other issue is in speed collection seen here:

The speed on one tube collecting off a high resolution digital encoder via modbus TCP/IP appears to have a lot of noise at the start of a run but then mellows out. I do have an averaging function with a window size of about twenty, but that window would fill far faster than the time this takes to settle. Chain slip, tension issues, bridle issues...a lot of things can be ruled out because it doesn't happen once running after the first few minutes. I'm wondering if I'm seeing some noise in the motor circuit itself, the drives produced coming up to speed but the noise lasts for a little while before tapering off which I find odd since it's not abrupt like I would expect. Perhaps my resolution is too high...I'm thinking about lowering it since it's like a few thousand PPR and likely overkill on their defaults...collect some more data and see but curious if this speed trend sparks any obvious insight from other individuals in the field.

The signals on mA are set to (weak cycle) for smoothing as well...I've considering upping these a little to perhaps handle some noise but I need to respect real time circuit sensitivity to actual change as well.

As always thank you and appreciate everyone's perspective and feedback!