jillgeorge18

Member

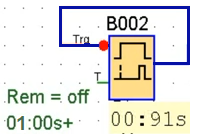

Hi there, I have three pumps, I have to start first pump for 8 minute and after that it should be turned off and other one start simultaneously and it should be run for 8 minute and same must be turned off after the time delay and the now 3rd one should start for 8 minute and should be turned off after the time delay and process would continue from beginning...Any help...Thanks in advance...All this based on float switch in tank

Last edited: